An air shower is a device used to remove contaminants from people or objects before they enter a cleanroom or other controlled environment. It works by blowing high-velocity, HEPA-filtered air over the person or object to remove any particles that may be on their surface or clothing.

A HEPA (High-Efficiency Particulate Air) filter is a type of air filter that can remove at least 99.97% of particles that are 0.3 microns in size or larger. HEPA filters are commonly used in cleanrooms, hospitals, and other environments where air quality is critical. In an air shower, HEPA filters are typically used to clean the air that is blown over the person or object being decontaminated. The HEPA filter removes any particles that may be present in the air, ensuring that the air shower is effective at removing contaminants. Overall, the combination of an air shower and a HEPA filter is a highly effective way to remove contaminants and maintain a clean environment in critical areas such as cleanrooms and laboratories.

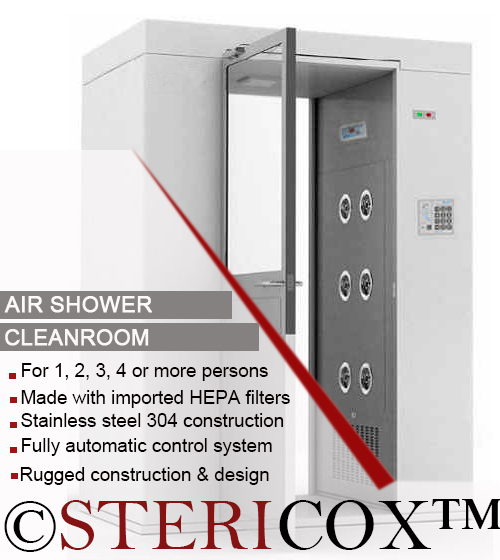

An air shower is a two doors walk-through dust removal system, which is fitted prior to cleanroom entrance. The purpose of setting up air shower system is to control the risk of spreading contaminants in the cleanroom environment by removing particulate matter on the personnel by throwing class 100 airflow. The air shower machine throws high velocity HEPA filtered air through jet nozzles which removes particulate matter (includes solid and liquid particles suspend in air and some of them are hazardous in nature). The contaminated air is again filtered and re-circulated. With-in seconds, the person entering into air shower comes out entirely cleans i.e. free from harmful dust. Electronics and Pharmaceutical productions and animal breeding laboratories are some of areas where air showers are extensively used.

We are ISO and CE certified air shower manufacturers in India. We have in house facility of design, construction and installation of air shower entry systems for laboratories, clean rooms and manufacturing areas etc. These systems are carefully constructed at our factory, tested at various parameters then dispatched to the client's site. Our air shower cabinets are designed with corrosion resistant materials (Stainless steel or powder coated MS), fitted with easy to use controls and safety arrangements; filters are easily replaceable whenever needed.

Our air shower entry systems are custom designed and constructed as per requirements of the customers and sold at industry leading price in India and also export to USA, UK, Greece, UAE, Netherland and Australia.

No. of persons per cycle

Standard models are made only for 1 person per cycle. To meet the needs of large number of workers, we can also design air showers with 2, 3 and 4 persons per cycles. They can also be fitted in series and parallel to meet demand of large number of workers.

Exit Type

Our air showers are available of throughout type entry-exit, L type entry-exit and one-way entry and two way exit type.

Construction

Made of only corrosion resistant materials; we use either high grade stainless steel anti-microbial properties or powder coated MS for construction.

Doors

Two doors are fitted in a system, one at entrance and one at exit. Doors are also made of stainless steel or powder coated MS. Handles and hydraulic door closers are fitted for easy access of door. Electromagnetic interlocking allows opening of single at one time; thus, prevents unwanted contamination inside the machine. There is also emergency switch; by pressing it, both doors open immediately.

Blower

Properly balanced motor blower of standard make, fitted with suspension system for noise level reduction.

Flooring

Flooring or platform is made of either Stainless steel or Aluminum with detachable anti-slip PVC mat or equivalent material.

Fittings

Over all fittings such as handles, hinges and wires etc. are of any reputed brand and ISI marked.

Installation

Our engineering team visits your site and installs the machine properly. Demonstration and training is provided to all relevant staff.

TECHNICAL SPECIFICATIONS

| No. of Persons per cycle |

1, 2, 3 or 4 persons |

| Material of construction |

Aluminum / Powder coated MS / SS 304 |

| Flooring |

SS / Aluminum with detachable PVC mat |

| Doors |

2 doors with glass |

| Air filters |

HEPA filter and Washable pre-filters |

| Shower jet velocity |

18 - 22 m/s |

| Shower Duration |

0 - 120 seconds programmable |

| Nozzles |

SS nozzles 6, 12 or more |

| Nozzle position |

Left, right and top |

| Lighting |

Tube lights 1 or 2 as required |

| Blower |

Balanced motor blower with suspension |

| Air cleanliness |

ISO Class 5 (ISO 14644-1:1999 (E)) |

| Safety |

- Emergency stop button

- Indicator lights

- Door bell

|

| Optional |

- PLC & HMI control system

- UV Lamp

- Hour meter

|

Standard Sizes / Dimensions

| Model |

Internal Dimensions |

| STXAS001 |

700 x 850 x 2000 mm |

| STXAS002 |

700 x 1200 x 2000 mm |

| STXAS003 |

900 x 900 x 1950 mm |

| STXAS004 |

900x 1800 x 1950 mm |